Modern technology depends heavily on reliable energy storage. From smartphones and laptops to electric vehicles and renewable energy systems, batteries power the world around us. However, one persistent challenge continues to limit battery efficiency and sustainability — lifespan. Improving battery longevity not only reduces replacement costs but also minimizes environmental impact.

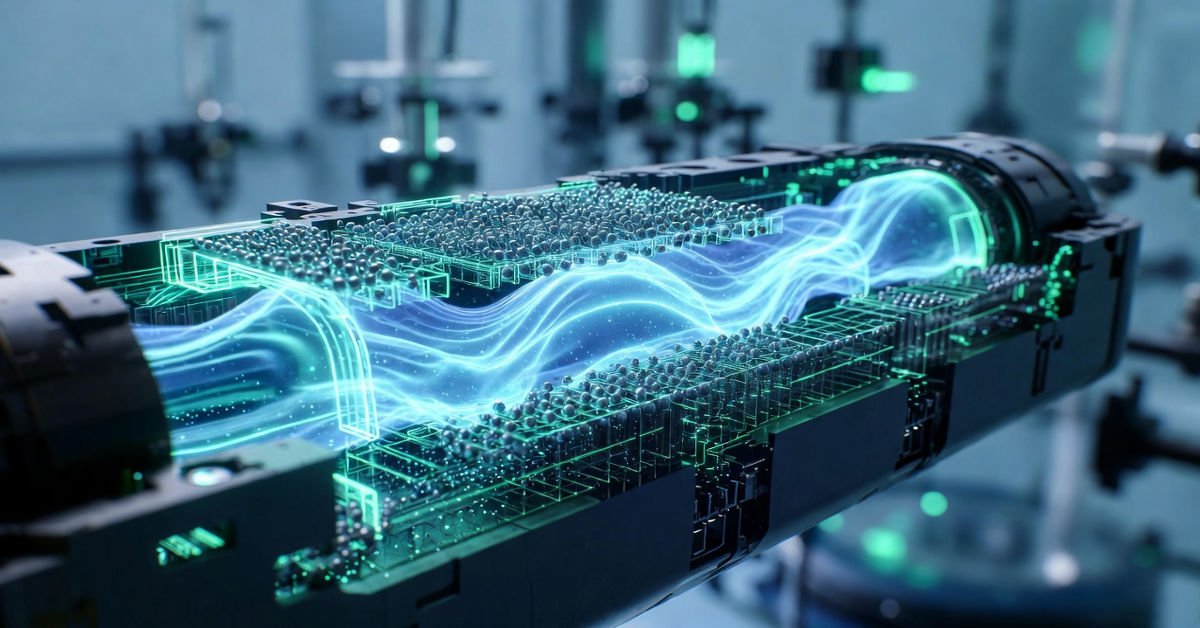

One of the most promising solutions lies in anode engineering, a field that focuses on enhancing the structure, materials, and chemical stability of the anode to extend battery life. Researchers and manufacturers worldwide are investing in advanced engineering techniques to create batteries that last longer, charge faster, and perform more safely.

This article explores how anode engineering improves battery lifespan, the technologies driving innovation, and why these developments matter for consumers, industries, and the future of clean energy.

Understanding the Role of the Anode in Battery Performance

In any rechargeable battery, the anode is one of the two primary electrodes responsible for storing and releasing energy. During charging, lithium ions move toward the anode, where they are stored until the battery is used again. During discharge, those ions travel back to the cathode, generating electricity.

Because the anode undergoes repeated chemical reactions, it experiences gradual wear over time. This degradation directly impacts battery capacity and lifespan.

Core Functions of an Anode

| Function | Description | Impact on Lifespan |

|---|---|---|

| Ion Storage | Holds lithium ions during charging | Higher stability improves cycle life |

| Electron Flow | Enables current movement through the circuit | Efficient flow reduces heat |

| Structural Support | Maintains electrode integrity | Prevents cracking and capacity loss |

| Chemical Stability | Resists unwanted reactions | Reduces long-term degradation |

When the anode fails, the entire battery performance declines. That is why engineering improvements at the anode level can produce dramatic results.

Why Battery Lifespan Matters More Than Ever

As industries transition toward electrification, longer battery life is no longer a luxury — it is a necessity.

Electric vehicles must maintain performance for years without significant range loss. Grid storage systems need durable batteries to support renewable energy. Even everyday devices benefit from fewer charging cycles.

Key Benefits of Longer Battery Lifespan

| Benefit | Explanation |

|---|---|

| Lower Ownership Costs | Fewer replacements reduce expenses |

| Environmental Sustainability | Less battery waste lowers pollution |

| Improved Safety | Stable materials decrease overheating risks |

| Better User Experience | Devices maintain performance longer |

| Stronger Energy Reliability | Critical systems avoid unexpected failures |

Investing in lifespan improvement is both economically and environmentally responsible.

Common Causes of Anode Degradation

Before understanding how engineering solves the problem, it is important to know what causes anodes to fail.

Major Degradation Factors

| Cause | What Happens | Result |

|---|---|---|

| Volume Expansion | Materials swell during charging | Leads to cracking |

| SEI Layer Growth | Protective film thickens over time | Reduces efficiency |

| Lithium Plating | Metallic lithium forms on the surface | Can cause short circuits |

| Particle Fracture | Repeated stress breaks materials | Capacity drops |

| Heat Stress | High temperatures accelerate reactions | Faster aging |

These challenges have guided researchers toward smarter material choices and structural innovations.

Advanced Materials Transforming Anode Engineering

Material science sits at the heart of lifespan improvement. Traditional graphite anodes have served the industry well, but next-generation materials promise significantly better durability.

Comparison of Emerging Anode Materials

| Material | Advantages | Challenges | Lifespan Potential |

|---|---|---|---|

| Graphite | Reliable and affordable | Limited capacity | Moderate |

| Silicon | Extremely high capacity | Expands significantly | High with engineering support |

| Lithium Titanate | Excellent safety and fast charging | Lower energy density | Very High |

| Tin-Based Alloys | Strong conductivity | Structural stress | High |

| Carbon Nanotubes | Flexible and durable | Expensive | Very High |

Among these, silicon has gained particular attention due to its ability to store nearly ten times more lithium than graphite. However, it expands dramatically during charging — a problem that modern engineering is actively solving.

Silicon Anodes: A Breakthrough with Engineering Challenges

Silicon represents one of the biggest opportunities in battery development. Its high storage capacity could enable smaller batteries with longer runtimes.

However, silicon can expand by up to 300 percent when absorbing lithium ions. Without engineering support, this expansion causes fractures that shorten battery life.

Engineering Solutions for Silicon Stability

| Technique | How It Helps |

|---|---|

| Nanostructuring | Reduces mechanical stress |

| Composite Blends | Combines silicon with graphite for balance |

| Elastic Binders | Allow materials to expand safely |

| Protective Coatings | Prevent unwanted reactions |

| Porous Designs | Create space for expansion |

These innovations are steadily moving silicon batteries closer to widespread commercialization.

Structural Design Innovations Extending Battery Life

Beyond materials, physical design plays a crucial role in preventing damage.

Engineers now focus on building flexible internal structures that can handle repeated charge cycles without breaking down.

Structural Strategies in Modern Anodes

| Strategy | Benefit |

|---|---|

| Hollow Particles | Absorb expansion pressure |

| Layered Architecture | Improves mechanical strength |

| 3D Conductive Networks | Enhance electron movement |

| Gradient Materials | Reduce stress between layers |

| Reinforced Frameworks | Maintain long-term stability |

Such designs ensure that the anode remains intact even under demanding usage conditions.

The Role of the Solid Electrolyte Interphase (SEI)

A lesser-known but critical factor in battery lifespan is the solid electrolyte interphase, commonly called the SEI layer. This thin protective film forms naturally during early charge cycles.

When stable, it protects the anode from further chemical reactions. When unstable, it consumes lithium and reduces capacity.

SEI Optimization Techniques

| Method | Outcome |

|---|---|

| Electrolyte Additives | Promote stable film formation |

| Artificial SEI Layers | Provide early protection |

| Surface Treatments | Improve chemical resistance |

| Low-Temperature Formation | Enhances uniformity |

| Advanced Salts | Reduce degradation |

Careful SEI management is now considered essential for long-life batteries.

Manufacturing Precision and Quality Control

Even the best materials cannot perform well without precise manufacturing. Small defects can grow into major failures after hundreds of cycles.

Modern production lines increasingly rely on automation and analytics to improve consistency.

Quality Factors That Influence Lifespan

| Factor | Importance |

|---|---|

| Coating Uniformity | Prevents uneven reactions |

| Particle Distribution | Ensures stable conductivity |

| Moisture Control | Avoids chemical damage |

| Compression Accuracy | Maintains structural balance |

| Cleanroom Standards | Reduces contamination |

High-quality manufacturing translates directly into longer battery service life.

Fast Charging Without Rapid Degradation

Consumers want faster charging, but rapid energy flow can strain the anode. Engineering advances now allow batteries to handle higher currents without severe damage.

Techniques Supporting Fast-Charge Longevity

| Technology | Lifespan Benefit |

|---|---|

| Advanced Thermal Control | Prevents overheating |

| Smart Charging Algorithms | Optimize current flow |

| Lithium Titanate Anodes | Resist plating |

| Conductive Additives | Reduce resistance |

| Pulse Charging | Limits stress buildup |

These approaches help balance speed with durability.

Sustainability and Environmental Impact

Improving anode lifespan has significant environmental advantages. Longer-lasting batteries reduce raw material demand and lower recycling pressure.

Environmental Gains from Lifespan Improvement

| Area | Positive Impact |

|---|---|

| Resource Extraction | Less mining required |

| Carbon Emissions | Lower manufacturing footprint |

| Waste Reduction | Fewer discarded batteries |

| Energy Efficiency | Better long-term storage |

| Circular Economy | Supports reuse strategies |

As sustainability becomes a global priority, durable battery design is increasingly important.

Artificial Intelligence in Anode Development

Artificial intelligence is accelerating innovation by identifying material combinations and predicting failure patterns faster than traditional testing methods.

AI Contributions to Anode Engineering

| Application | Advantage |

|---|---|

| Predictive Modeling | Anticipates degradation |

| Material Discovery | Finds stronger compounds |

| Process Optimization | Improves production yields |

| Real-Time Monitoring | Detects anomalies early |

| Lifecycle Forecasting | Helps plan replacements |

AI-driven research is expected to shorten development timelines dramatically.

Safety Improvements Through Better Anodes

Battery safety has always been a critical concern. Engineering improvements at the anode level reduce the likelihood of dangerous events such as thermal runaway.

Safety Enhancements

| Innovation | Safety Benefit |

|---|---|

| Non-Flammable Electrolytes | Reduce fire risk |

| Stable Crystal Structures | Prevent collapse |

| Heat-Resistant Coatings | Improve tolerance |

| Dendrite Suppression | Avoid internal shorts |

| Smart Sensors | Enable early warnings |

Safer batteries encourage wider adoption across industries.

Real-World Applications Driving Demand

Anode lifespan improvement is not just a laboratory goal — it directly impacts multiple sectors.

Industries Benefiting from Advanced Anodes

| Industry | Why Lifespan Matters |

|---|---|

| Electric Vehicles | Longer range retention |

| Consumer Electronics | Fewer replacements |

| Renewable Energy Storage | Reliable grid support |

| Aerospace | High reliability required |

| Medical Devices | Consistent performance |

As these industries grow, demand for durable batteries will continue rising.

Future Trends in Anode Engineering

The next decade is expected to bring transformative changes in battery design.

Emerging Trends to Watch

| Trend | Expected Outcome |

|---|---|

| Solid-State Batteries | Increased safety and lifespan |

| Silicon-Dominant Designs | Higher capacity |

| Self-Healing Materials | Reduced cracking |

| Hybrid Anodes | Balanced performance |

| Ultra-Thin Electrodes | Faster charging |

These innovations could redefine energy storage standards worldwide.

Challenges Still Facing Researchers

Despite rapid progress, several hurdles remain before next-generation anodes achieve mass adoption.

Ongoing Challenges

| Challenge | Description |

|---|---|

| High Production Costs | Advanced materials remain expensive |

| Scalability | Lab success must translate to factories |

| Long-Term Testing | Real-world validation takes years |

| Supply Chain Constraints | Material sourcing can be complex |

| Integration | Compatibility with existing systems |

Addressing these issues will require collaboration across academia, industry, and policymakers.

Expert Perspective: Why Anode Engineering Is a Strategic Investment

Energy experts increasingly view anode innovation as a strategic priority rather than a niche research area. Batteries with longer lifespans reduce operational risk, support electrification, and strengthen energy independence.

Organizations investing early in advanced battery technology are likely to gain a competitive advantage as global demand accelerates.

Moreover, governments and private institutions are funding research initiatives to ensure sustainable progress in energy storage.

Practical Takeaways for Businesses and Consumers

Understanding anode engineering helps stakeholders make smarter technology decisions.

What to Look for in Long-Life Batteries

| Feature | Why It Matters |

|---|---|

| Advanced Materials | Improve durability |

| Strong Cycle Ratings | Indicate longevity |

| Thermal Management | Protect internal components |

| Certified Safety Standards | Ensure reliability |

| Warranty Coverage | Reflect manufacturer confidence |

Choosing products built with lifespan-focused engineering can deliver better long-term value.

Conclusion

Anode engineering is reshaping the future of battery technology. By addressing the root causes of degradation, researchers are unlocking new levels of durability, safety, and efficiency.

From silicon composites to AI-assisted material discovery, each innovation brings the world closer to batteries that last significantly longer than today’s standards. These advancements will not only enhance everyday devices but also support large-scale transitions toward electric transportation and renewable energy.